WCU steams through new era with $33 million plant

By Benny Smith

Thanks to new boilers, the new steam plant will be able to give WCU 110,000 pounds per hour at 90% efficiency, compared to the old plant that is currently outputting 107,000 PPH at only 50% efficiency.

When someone turns on the hot water or adjusts a thermostat for heat at Western Carolina University, rarely do they think about the process that goes into place to deliver it.

But what if the water or building never gets warm?

Then, that expectation is not met, and disappointment may ensue. Even worse, the university is forced to shut down because it can no longer provide heat or hot water. But thanks to a new $33 million steam plant, for which the university is holding a ribbon-cutting ceremony Friday, Oct. 21, the chances of this ever happening will be small.

“Like most infrastructure, nobody cares about it until it fails,” said Terry Riouff, steam plant supervisor. “The new steam plant gives us redundancy. We didn’t have that with the old steam plant.”

The two fuel storage tanks that are used as a backup source of fuel were relocated to the back of the plant.

Friday’s event signifies a new era for WCU and how it uses steam to provide hot water and heat throughout most of the campus. The new facility is a two-story structure, with boilers, piping and a control room located on the main floor. Water pumps, water treatment equipment and compressors are on the lower floor. While the new facility also has its own smokestack, the design approved by the WCU Board of Trustees keeps the current smokestack as a nod to university history.

The original steam plant started using coal as a fuel source in the early 1920s. However, the plant moved away from coal as fuel source and then the plant was shifted to a fuel/oil source. A shift to natural gas was performed within the last decade.

WCU has used a primitive coal-fired boiler system to provide heat on campus. The original smokestack is one of the most iconic features on the WCU campus. Photos dating back to the 1920s show how one could tell exactly where they were on campus in proximity to the smokestack.

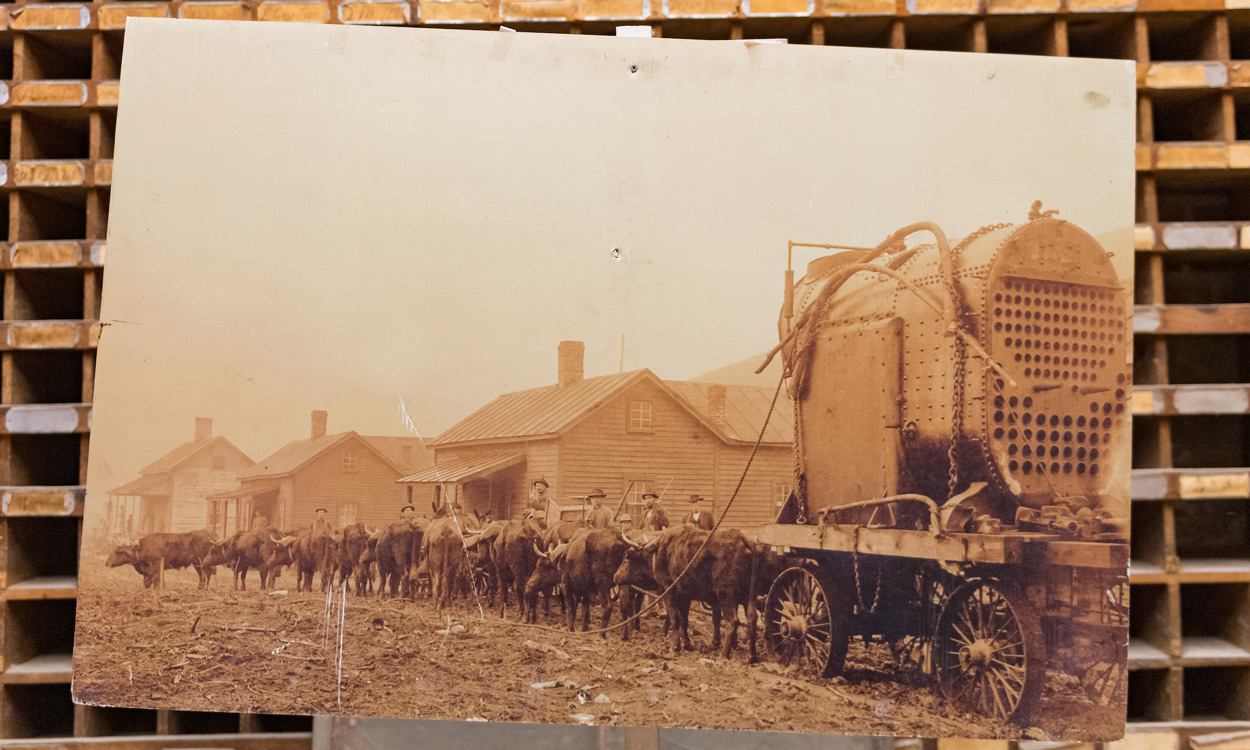

A photo of the old boiler.

The old steam plant became known as the poster child for infrastructure needs and deferred maintenance issues across the University of North Carolina System.

Possessing a new confidence of providing constant heat and steam to campus is a big relief to WCU facilities team members like Joe Walker, associate vice chancellor for facilities management, Riouff and many others who have been working to repair it the last few decades.

“This was my top capital priority when I started working here more than 20 years ago,” Walker said. “I knew the old plant would not last forever. Now, I can sleep better at night knowing that we have a new facility. Whenever I do decide to retire from the university, at least the person behind me can be assured we have the latest operational technology to provide heat for our campus for years to come.”

Top university officials have been concerned for years that the university was just one harsh winter or one catastrophic mechanical failure away from a complete campus shutdown because of a lack of steam to heat buildings and provide hot water. That type of shutdown nearly occurred in the winter of 2015 when the oldest boiler failed, resulting in the need to install costly temporary boilers with a projected lifespan of only 10 years.

Terry Riouff, steam plant supervisor, poses inside the old boiler.

A portion of the original plant will remain with the existing facade facing Central Drive, with its large windows as a visually appealing architectural element. The new facility will include a lobby, administrative offices, and space to display some of the old plant’s equipment. The plant’s original steam whistle once used to signal the start and end of a workday, midday lunch break and, with a long continuous blast, special events or warnings, will be installed with the new plant.

Like the current steam plant, the new facility will operate using natural gas, with No. 2 fuel oil as a backup source of fuel. Fuel storage tanks will be relocated to the rear of the new building. The new steam plant will be able to give WCU 110,000 pounds per hour at 90% efficiency compared to the old plant that is currently outputting 107,000 PPH at only 50% efficiency. Once the new plant is fully operational, the old plant will be decommissioned.

Walker credits the late Chancellor David O. Belcher and his executive team as important advocates for funding to address the need for a new steam plant. Belcher was heard many times describing it as “one of the most acute and critical infrastructure needs facing our campus.” He even christened it the ‘steam museum.’

Walker said Chancellor Kelli R. Brown continued that support for the steam plant when she arrived on campus, providing whatever resources were needed to keep the plant going until the new one was online.

As part of the 2017 state budget, legislators appropriated $750,000 for WCU to begin planning a design for a replacement of the steam plant, with an initial installment of $16.5 million included in the state budget approved in 2018. The second $16.5 million installment was included in the 2020 budget.

“What a great day, to celebrate the near completion of a vital infrastructure for the operation of our campus that was nearing 100 years old,” said Chancellor Kelli Brown. “This has been our top capital improvement project priority since 2012. To have this magnificent new facility that will provide our heating needs far into the future truly is a blessing to the entire WCU campus community.”

Riouff and steam plant construction project manager Don Hair said although the ribbon-cutting is Friday, they anticipate it will not be fully operational until sometime early next month.

“I agree with Joe, I can now sleep better at night with the new steam plant,” Riouff, who is credited as the main staff employee who has kept the old plant running far beyond its intended life.”