Rapid Center uses 3D printers to make face shields for faculty, staff

By Bill Studenc

After spending much of the spring and summer using the 3D printing technology in Western Carolina University’s Rapid Center to help develop personal protective equipment for use by health care workers in their battle with COVID-19, faculty, students and staff in the College of Engineering and Technology have turned their attention to helping employees return safely to campus this fall.

Under the supervision of Patrick Gardner, director of the Rapid Center, and Monty

Graham, the center’s engineering project coordinator, several students checked out

3D printers over the summer and used them from home to help produce face shields for

the medical community. By midsummer, those efforts had resulted in the delivery of

approximately 3,000 shields to health care workers across Western North Carolina through

WCU’s Center for Community Engagement and Learning.

Agencies receiving shields from WCU included Blue Ridge Health, Harris Regional Hospital, Haywood Regional Hospital, Cherokee Hospital, Appalachian Mountain Community Health, Vecinos, Jackson County Health Department, Swain County Health Department, WNC Eye Associates Surgery Center, Brookdale Senior Living Centers, Western Carolina Medical Society, Mercy Urgent Care, Bryson City Urgent Care, Madison County Health Department, Macon County Health Department, Asheville Buncombe Community Christian Ministries and WNC Community Health Services.

At that point, Gardner thought he was finished making face shields – until Interim Provost Richard Starnes placed an order for 1,400 shields for use by faculty and staff this fall. Gardner quickly assembled a team to get that order filled and delivered.

May graduate Anthony “A.J.” Mongold, now seeking his master’s degree in technology at WCU and one of the original students 3D printing visors from his apartment, prepared the Maker Space in the Belk Building for mass production of 3D-printed visors and performed most of the maintenance to keep machines operating.

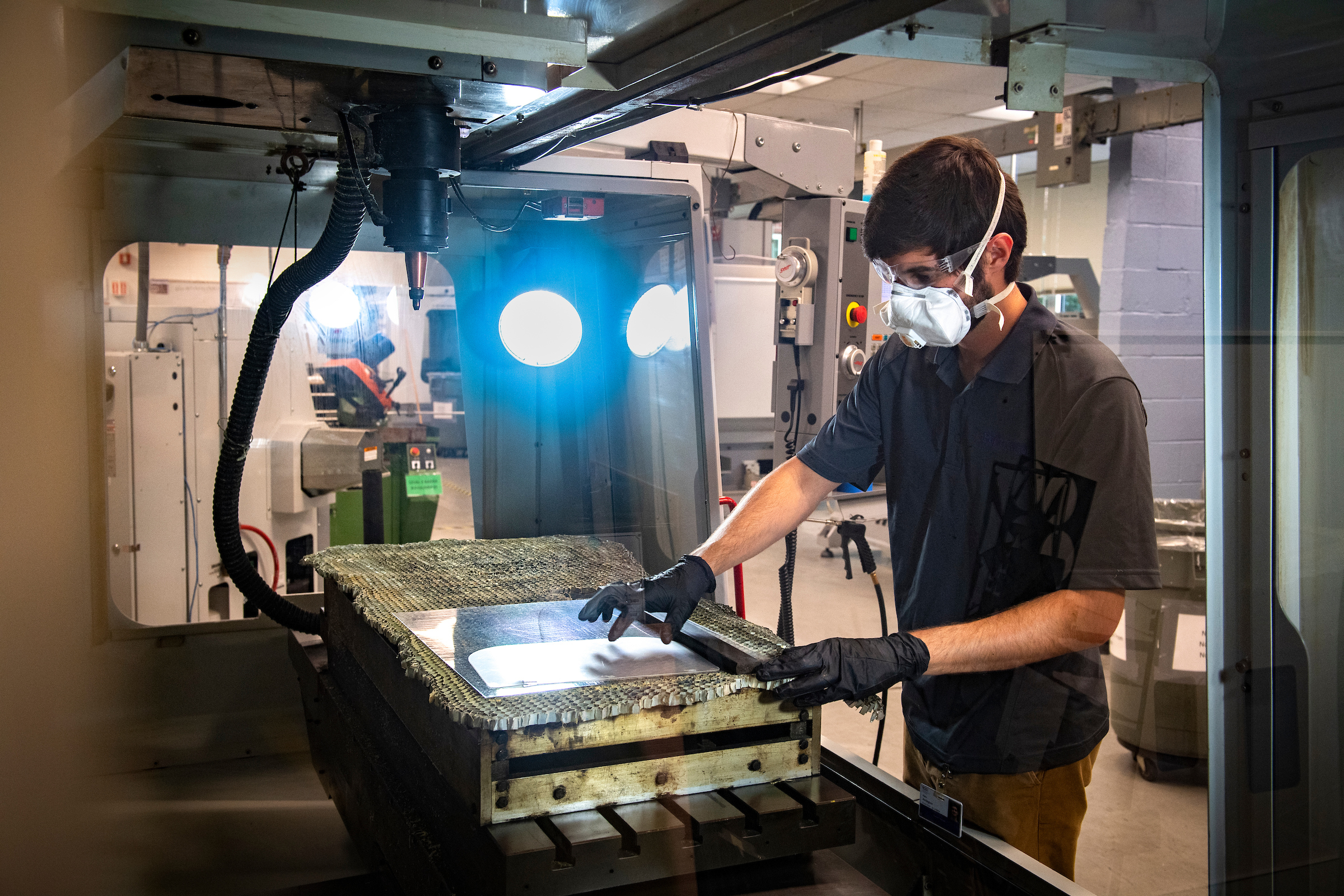

Senior Parker Arrington, an engineering intern in the center, took over the 3D printing operation and operated a laser cutter to make the plastic shields. In the background, Rapid Center engineers Brett Banther and Shawn Lyvers delivered visors they were 3D printing at home. The 1,400 face shields were produced and delivered by Monday, July 27.

“It was rewarding to know the work we performed over the summer was helpful to health care workers and first responders across Western North Carolina, and it is equally rewarding to know that we are playing a role in ensuring a safe return to work for our faculty and staff colleagues,” Gardner said. “The Rapid Center was made for this type of assistance – look at a customer’s need, and develop a solution that helps them move forward with their innovation.”