Collaborative innovation drives solutions in Catawba County

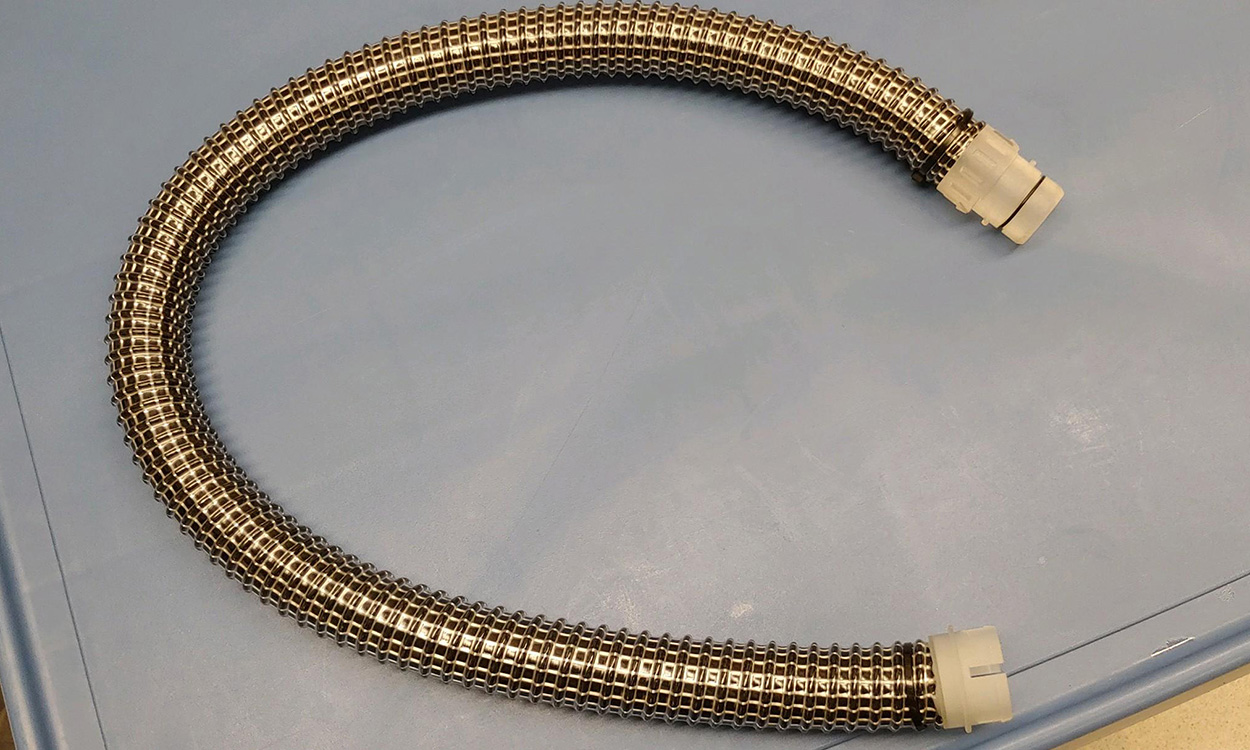

Reserve Powered Air Purifying Respirator (PAPR) air hoses at Catawba Valley Health System are outfitted with replicated connectors created by Western Carolina University’s Rapid Center.

HICKORY, NC – With the onset of COVID-19, health care systems across the country began assessing readiness in the event of a surge of COVID-19 patients. Catawba Valley Health System in Catawba County, North Carolina, was no different.

The system’s Director of Emergency Management & Environmental Compliance, Mike Helton, reviewed the hospital’s reserve inventory of personal protective equipment (PPE), which included a back-up supply of Powered Air Purifying Respirators (PAPRs). PAPRs are used by healthcare staff who cannot be properly fitted with the standard N-95 mask when caring for patients with respiratory illness.

PAPRs work by blowing purified air through a hose that connects from the blower to a hood worn over the entire head. Helton found that 20 of the hospital’s reserve PAPRs needed new hoses. After a nationwide supply chain search, he learned the hoses with the correct connectors for their units had been discontinued, and the existing but small supply of discontinued parts had already been procured by other healthcare providers in the same situation.

“When we exhausted all possibilities with potential vendors nationwide, we appealed to Catawba County’s Emergency Management team for help,” Helton said. “They were able to procure replacement hoses, but the connectors that fit the ends of the hoses to the PAPR equipment were still needed.”

Monty Graham, engineering project coordinator for Western Carolina University’s Rapid Center, checks the fit for custom 3-D printed connectors for Catawba Valley Health System’s reserve PAPR equipment.

As one of the lead partners in Catawba County’s coordinated response to COVID-19, Catawba County Emergency Management maintains awareness of emergency COVID-19 resources available to counties from local, state, federal and other emergency partners.

“Knowing the priority being placed on locating additional PPE at the state and federal levels, there was a chance we might be able to find the connectors through North Carolina Emergency Management,” said Bryan Blanton, Catawba County’s emergency services director. “We made a formal request through the state, and due to the high demand for this kind of equipment, our search turned up empty.”

Not to be deterred, the county’s emergency management team brainstormed solutions and pivoted in another direction altogether: working with a manufacturing partner to replicate the connectors. Blanton initially contacted the local Manufacturing Solutions Center in Conover to discuss this possibility.

“The Manufacturing Solutions Center was very willing to help, but they didn’t have the type of machine that could make the fitting non-porous,” Blanton explained. “They referred us to the Rapid Center at Western Carolina University and helped open the door to what turned out to be a great solution.”

Using a method called “reverse engineering,” engineers at Western Carolina University’s Rapid Center developed a 3D model of retrofit connectors. Adam Griffin, senior mechanical engineering major from Cashiers, met a representative of Catawba County’s emergency management team in Asheville to deliver prototype connectors and conducted a fit check on the spot. This allowed the Rapid Center to immediately begin printing 20 sets of connectors on the center’s 3D printers.

Within a few weeks, Catawba Valley Health System had the connectors and 20 more viable PAPRs in its surge reserves.

“It was rewarding to know that the work we performed for Catawba Valley Health System doubled the number of PAPR units they had available for emergency response,” said Patrick Gardner, Rapid Center director. “The Rapid Center was made for this type of assistance – look at a customer’s need, and develop a solution that helps them move forward with their innovation.”

“This project with Catawba County represents just one of many recent efforts by the College of Engineering and Technology to take advantage of the expertise of its faculty, staff and students and the capability of its research and development equipment to help solve a shortage of face shields and other personal protective gear needed by medical workers and first responders in the face of the coronavirus disease crisis,” said Jeff Ray, dean of the College of Engineering and Technology.

“WCU’s Rapid Center and College of Engineering and Technology are committed to the economic development, health and safety of our communities in Western North Carolina,” Ray said.